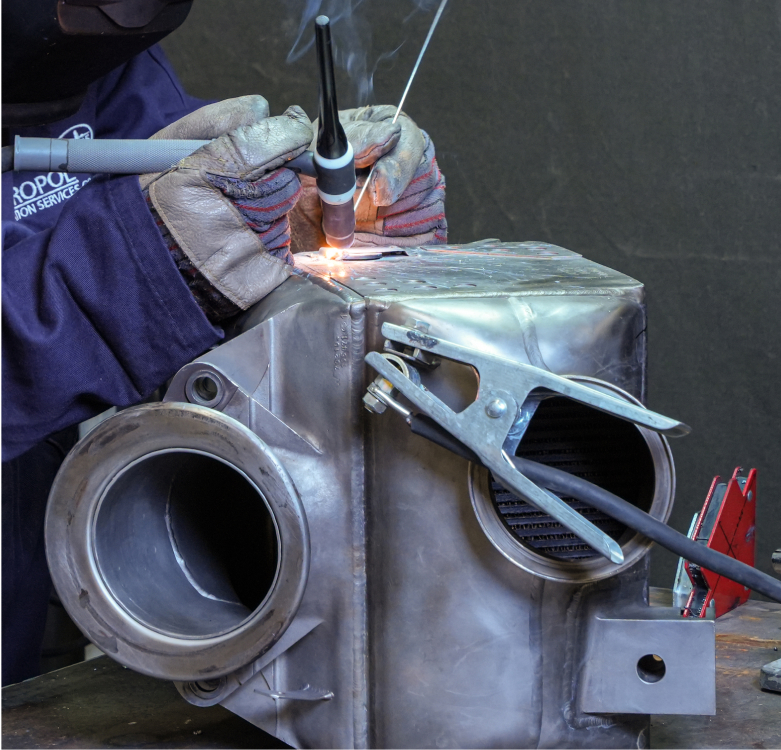

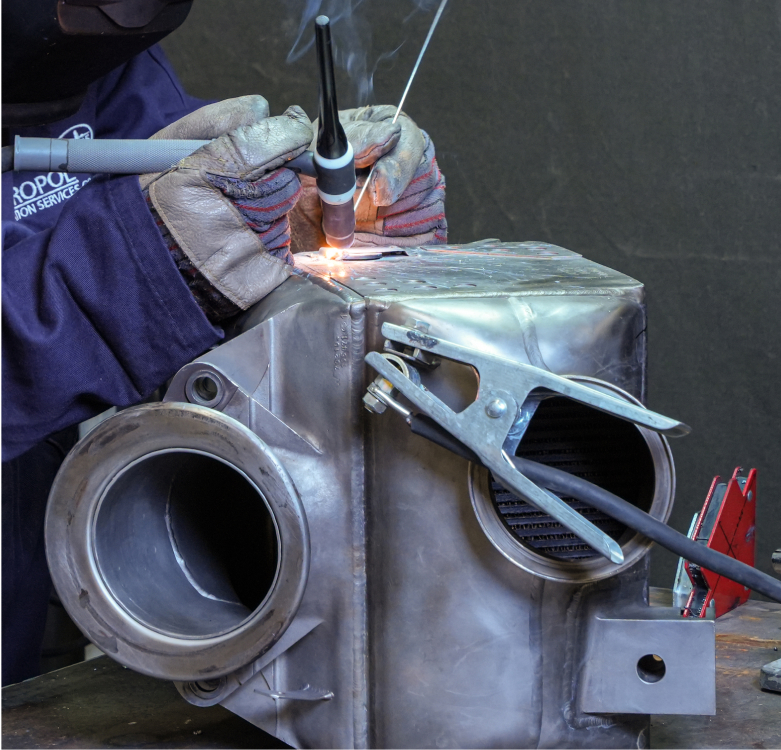

Welding

Welding Services at Aeropol

We provide specialized in-house welding services that meet the demanding standards of aviation Maintenance, Repair, and Overhaul (MRO). With deep expertise in aviation-grade materials and stringent adherence to industry regulations, our welding services are designed to restore and maintain aircraft components with the utmost precision, safety, and reliability.

Aviation-Grade Welding Techniques

Our team is adept in advanced welding techniques tailored to the aviation industry’s unique requirements. We utilize TIG (Tungsten Inert Gas) welding for its high precision and ability to handle thin materials without compromising strength and MIG (Metal Inert Gas) welding for robust joins in larger components. These techniques are crucial for handling aviation-specific alloys and metals, ensuring that each weld is both structurally sound and highly resilient to operational stresses.

Gas Welding

Gas welding, also known as oxy-acetylene welding (OAW), is a process that uses a flame from the combustion of oxygen and a fuel gas (typically acetylene) to melt and join metals. In the aerospace industry, this method has been used for welding aircraft components, especially in the repair of parts made of aluminum, steel, and other light alloys.

Arc Welding

Arc welding, encompassing processes like SMAW, MIG, TIG, and FCAW, plays a critical role in the aerospace industry. The ability to weld a wide variety of materials, combined with its high efficiency and strong welds, makes arc welding essential in both aircraft manufacturing and repair. MIG and TIG welding are particularly favored for their precision, while SMAW and FCAW are used for structural or field repairs.

Quality Assurance for Flight Safety

Each weld is subject to stringent quality control and inspection procedures aligned with aviation regulatory standards. We employ precise, multi-stage inspections, including Non-Destructive Testing (NDT) when needed, to verify the strength and integrity of every weld. Our commitment to meticulous quality assurance provides airlines and other aircraft operators with peace of mind, knowing that their aircraft components are restored to the highest operational and safety standards.

Dedicated to Aviation MRO Needs

Aeropol’s welding services support a wide range of MRO needs, from essential structural repairs to the fabrication of custom aviation parts. Our in-house team is skilled in managing repairs under tight timelines while maintaining the quality and durability required for aviation applications. With a strong focus on extending the lifecycle of critical aircraft components, Aeropol is a trusted partner that delivers safe, efficient and reliable aviation MRO support.