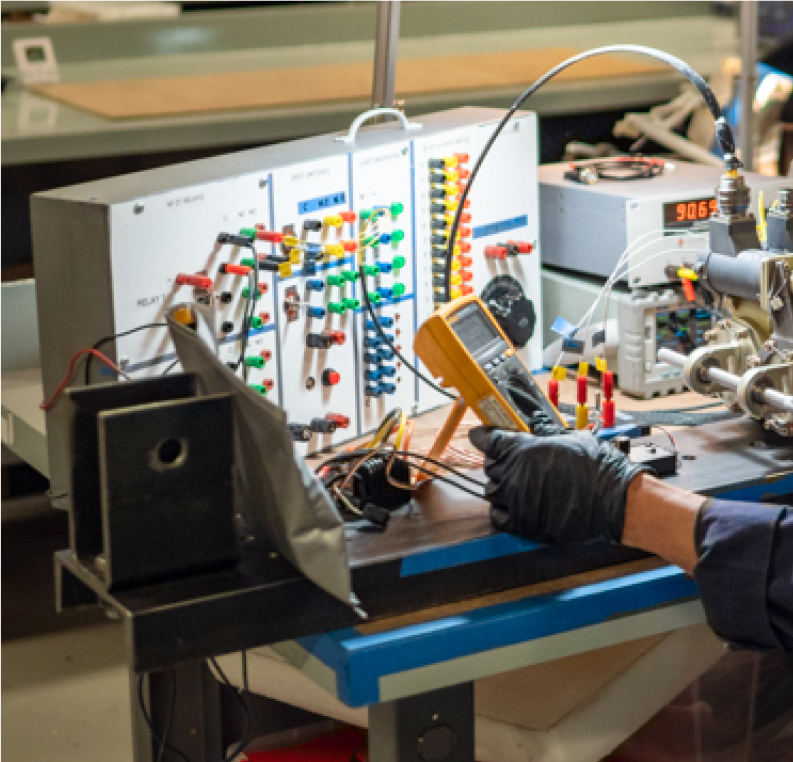

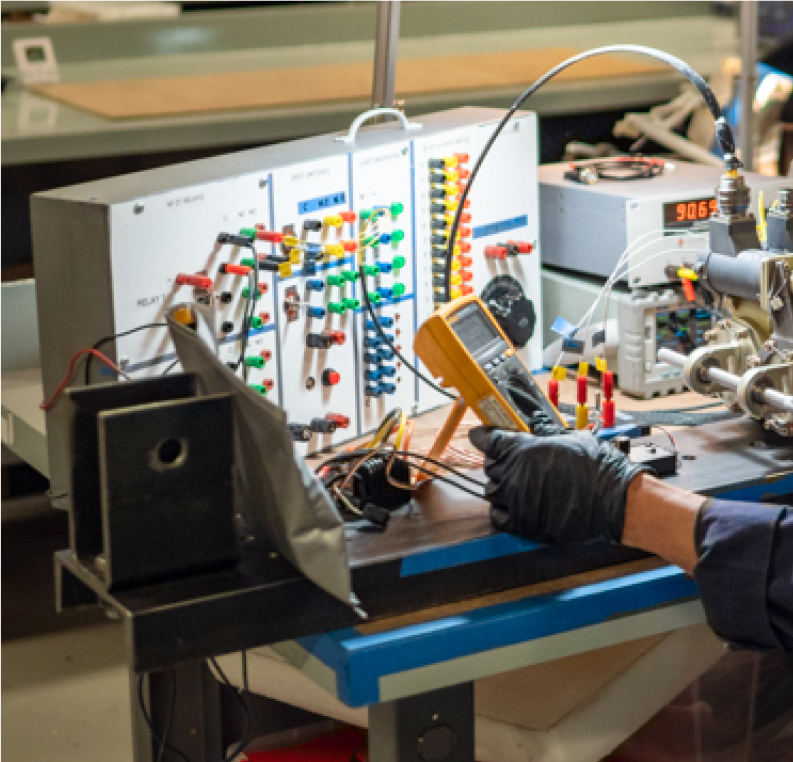

Component Repair & Overhaul

Aeropol’s streamlined processes and industry expertise ensure minimal downtime and enhanced aircraft performance, enabling operators to fly more frequently and generate higher revenue.

Pneumatic Systems: Aviation MRO Services

As a core component of our aviation MRO services, Aeropol offers specialized Pneumatic Systems MRO to support your aircraft’s operational integrity and performance. Our expert technicians are equipped with advanced skills in the maintenance, repair, and overhaul of pneumatic systems, ensuring tailored solutions for the unique requirements of your fleet. By focusing on safety, compliance, and efficiency, we strive to minimize downtime and keep your aircraft operating at peak performance.

Among Our Pneumatic Component MRO Services Are:

Air Cycle Machines (ACM)

We specialize in the maintenance of Air Cycle Machines, addressing common issues like component wear, imbalances, and airflow inefficiencies. Our solutions restore efficiency and ensure optimal cooling performance for a pleasurable flight experience inside the cabin.

Auxiliary Power Unit (APU) Cooling Fans

Our team provides thorough inspections, repairs, and balancing services for APU cooling fans. We ensure smooth operation and optimal cooling efficiency, preventing overheating and extending the APU’s service longevity.

Pneumatic Flow Control Valves

We expertly inspect, repair, and calibrate pneumatic flow control valves to eliminate leaks, restore pressure regulation, and optimize airflow management. Each valve undergoes rigorous testing to ensure reliable operation in demanding conditions.

Heat Exchangers

We offer specialized cleaning, inspection, and repair services for pneumatic heat exchangers. By addressing blockage restrictions, corrosion, and performance degradation, we help maintain efficient thermal transfer and system reliability on the aircraft.

Fly more frequently and generate higher revenue.

Ask Us HowHydraulics: Aviation MRO Services

We offer specialized Hydraulics MRO, ensuring your aircraft’s hydraulic systems operate efficiently with robust reliability. Our experienced technicians are skilled in hydraulic system maintenance, repair, and overhaul, offering services tailored to meet the demands of your fleet. Focusing on safety, compliance, and minimizing downtime, we work diligently to keep your aircraft in the air for seamless operation.

Among Our Hydraulic Component MRO Services Include:

Hydraulic Actuators

We provide expert maintenance and overhaul services for hydraulic actuators, addressing issues such as seal failures, internal leaks, and wear. Our thorough testing and precision repairs ensure reliable operation and extended service life.

Hydraulic System Oil Coolers

Our team specializes in cleaning, inspection, and repair of hydraulic system oil coolers, rectifying issues like blockages, corrosion, and heat transfer inefficiencies. We help your aircraft maintain optimal fluid temperature in your hydraulic system to ensure peak operational performance.

Engine-Driven Pumps

We deliver comprehensive services for engine-driven pumps, diagnosing and resolving issues like pressure loss, cavitation, noisy operation, and mechanical wear. Each pump is rigorously tested to ensure it meets or exceeds the highest performance for your aircrafts critical demand.

Hydraulic Control Valve Modules

Our technicians repair and overhaul hydraulic control valve modules with flawless precision, addressing internal leaks, pressure variances, Electrohydraulic Servo Valve discrepancies, Control Valve Hysteresis response, and Solenoid faults. With precise calibration and testing, we restore these critical components to ensure robust hydraulic system operation.

Altitude Blog

Aviation MRO guidance to keep your aircraft where it's meant to be - in the air.

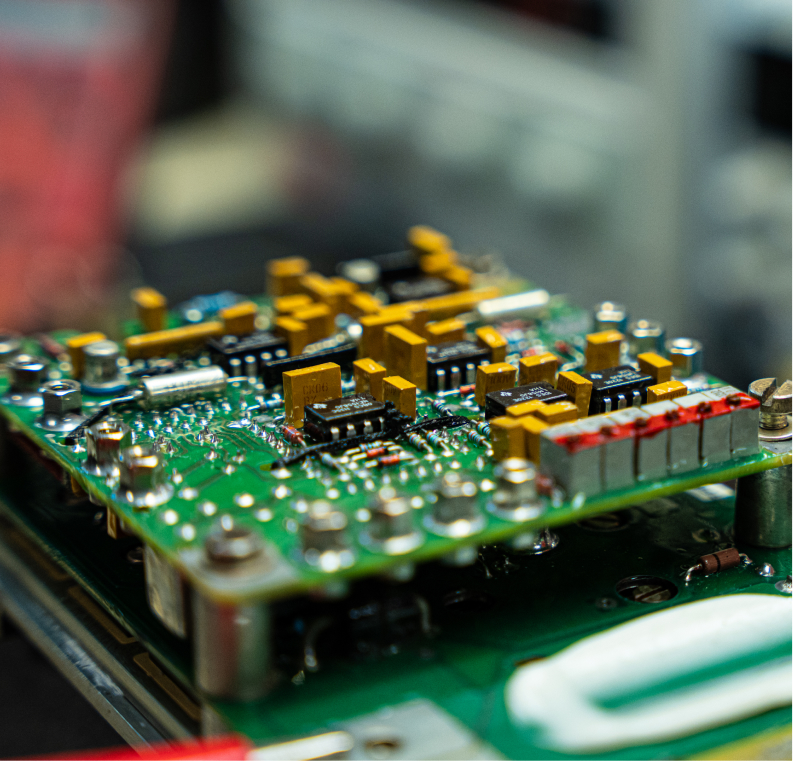

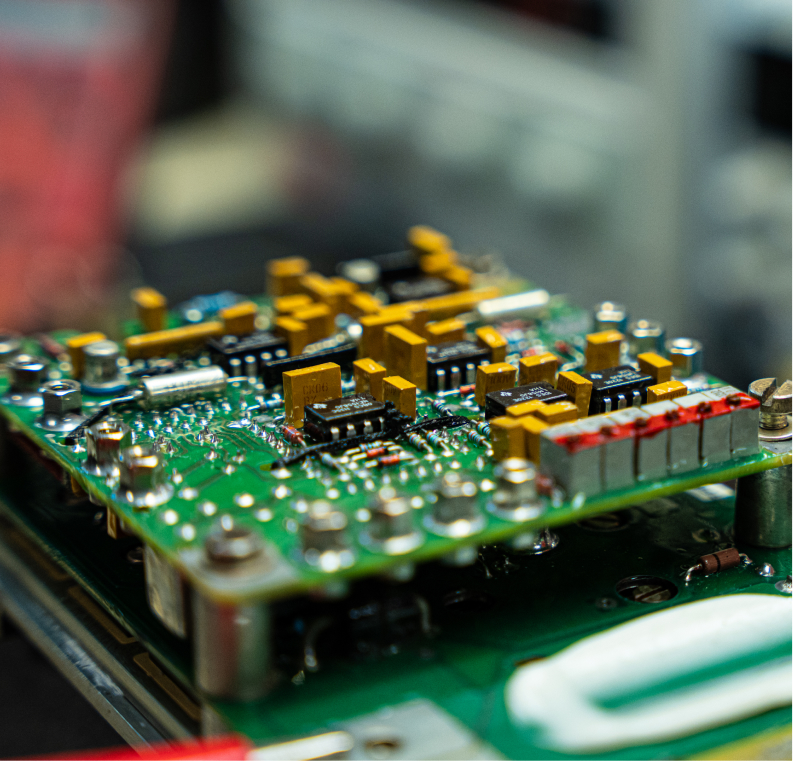

Read MoreElectrical Systems: Aviation MRO Services

Aeropol offers dedicated Electrical Systems MRO as part of our aviation maintenance services, supporting aircraft electrical systems with expert repair, overhaul, and preventive maintenance. Our team specializes in solutions for complex electrical systems, ensuring every component operates at peak capacity to enhance safety, reliability, and efficiency.

Among Our Electrical Component MRO Services Include:

Horizontal Stabilizer Actuators

We deliver specialized knowledge in the operation and maintenance of horizontal stabilizer actuators, addressing issues such as motor wear, electrical fault isolation, and gear assembly degradation. Our precise calibration ensures smooth and reliable operation for critical flight control systems.

Linear & Rotary Actuators

Our team provides comprehensive diagnostics and repair services for linear and rotary actuators, resolving issues like motor failures, signal interruptions, and mechanical wear. We restore these components to peak performance to ensure accurate travel and indication.

Flap Power Drive Units

We offer expert maintenance for flap power drive units, focusing on troubleshooting power delivery issues, restoring electrical integrity, and repairing mechanical components. Our work ensures consistent and reliable flap operation during take-off and landing.

Electrical Harness Inspection

Our harness services include detailed inspection, continuity testing, repairs to address damaged wiring, faulty connectors, or insulation related issues. We ensure robust and reliable electrical interface connections that are critical to the aircrafts electrical systems.

Fly more frequently and generate higher revenue.

Ask Us HowMechanical Systems: Aviation MRO Services

Aeropol’s Mechanical Systems MRO services are designed to keep your fleet’s mechanical systems performing with reliability, ensuring every part operates efficiently to meet the high standards in aviation. Our technicians have extensive experience in maintaining, repairing, and overhauling mechanical systems with a focus on durability, compliance to minimize service interruptions.

Among Our Mechanical Component MRO Services Include:

Flap Ball Screw Actuators

We provide meticulous maintenance and repair services for flap ball screw actuators, addressing issues such as ball and screw wear, excessive end play, lubrication deficiencies, and proper gimbal modulation. Our attention to precision during the assembly and testing process ensure smooth and reliable flap actuations for your aircraft.

Asymmetric Flap Brake Control Units

Our team specializes in the maintenance of asymmetric flap brake control units, resolving issues like internal wear, clutch slippage, solenoid response timing, and intermittent operational performance. We ensure robust asymmetric brake operation during the extension and retraction of your aircraft’s flaps.

Gearbox Assemblies

We deliver comprehensive diagnostics, repairs, and rebuilds for gearbox assemblies, focusing on resolving gear wear, bearing failures, and lubrication related issues. Our precision workmanship guarantee’s optimal power transmission, durability, and reliability whether in flight or on ground.

Altitude Blog

Aviation MRO guidance to keep your aircraft where it's meant to be - in the air.

Read MoreFuel Systems: Aviation MRO Services

As part of our expert aviation MRO services, we provide comprehensive Fuel Systems MRO to keep your aircraft performing at its best. Our skilled technicians have extensive experience in aviation fuel system maintenance, repair, and overhaul, offering solutions tailored to your fleet’s unique needs. With a focus on safety, compliance, and efficiency, we help ensure your aircraft are ready for takeoff with minimal downtime.

Among Our Fuel Component MRO Services Include:

Fuel Metering & Acceleration Manifolds

We specialize in the maintenance and repair of fuel metering and acceleration manifolds, addressing issues like flow inconsistencies, wear, and contamination. Our precision work ensures accurate fuel delivery and optimal engine performance.

Re-Fuel & De-Fuel Manifolds

Our team provides expert servicing for re-fuel and de-fuel manifolds, resolving issues such as seal degradation, flow restrictions, and pressure control malfunctions. We restore these systems to ensure safe and efficient fueling operations.

Fuel Tank Relief Valves

We inspect, repair, and calibrate fuel tank relief valves to address leaks, pressure regulation issues, pressure differential, and mechanical wear. Each valve is rigorously tested to ensure safety, reliability, and compliance with performance standards.

Fuel System Boost Pumps

Our services for fuel boost pumps include diagnostics, repair, and performance testing to resolve issues like cavitation, motor failures, impeller wear, and suction flow. We restore pumps to ensure consistent and efficient fuel flow to deliver proper fuel metering to the engines.